SPECIFICATIONS

Torque Specifications

REMOVAL AND INSTALLATION

Brake Pads - 325 mm (13 in) Brakes

Material

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTICE: Do not allow grease, oil, brake fluid or other contaminants to contact the pad lining material, or damage to components may occur. Do not install contaminated pads.

NOTE: Removal steps in this procedure may contain installation details.

- NOTE: The master cylinder reservoir should be half full to avoid

overflow when the brake caliper pistons are retracted.

Visual check. Extract the fluid with a syringe.

- Remove the wheel and tire. For additional information, REFER to Section 204-04.

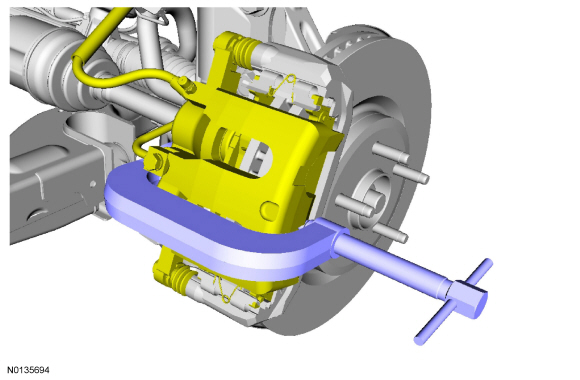

- NOTICE: Do not allow the brake caliper to hang from the brake

flexible hose and or damage to the hose may occur.

NOTICE: Make sure the brake caliper guide pin bolts are clean and free of debris or a binding condition may occur.

NOTICE: Do not allow the brake flexible hose to get twisted when the caliper is repositioned on the brake caliper anchor plate or damage to the hose may occur.

Relocate and support the component.- To install, tighten to 72 Nm (53 lb-ft).

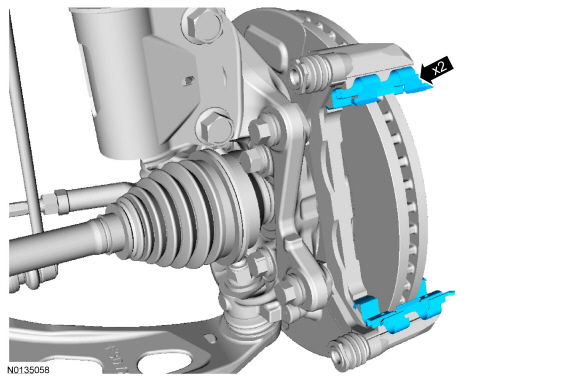

- NOTE: During installation, the coil in the center of the wire spreader spring must lie against the anchor plate and must not be in the raised position. If the coil in the center of the wire spreader spring does not rest against the caliper anchor plate, the spring is installed incorrectly and must be repositioned.

- NOTICE: Make sure the caliper pin boots are correctly seated

to prevent corrosion to the guide pins.

Visual check.

Installation

- NOTE: If installing new brake pads, make sure to install all new

hardware and lubricant supplied with the brake pad kit. Refer to the brake

pad instruction sheet when applying lubricant.

To install, reverse the removal procedure.

- Visual check.

Brake Pads - 352 mm (14 in) Brakes

Material

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTICE: Do not allow grease, oil, brake fluid or other contaminants to contact the pad lining material, or damage to components may occur. Do not install contaminated pads.

NOTE: Removal steps in this procedure may contain installation details.

- NOTE: The master cylinder reservoir should be half full to avoid

overflow when the brake caliper pistons are retracted.

Visual check. Extract the fluid with a syringe.

- Remove the wheel and tire. For additional information, REFER to Section 204-04.

- NOTICE: Do not allow the brake caliper to hang from the brake

flexible hose and or damage to the hose may occur.

NOTICE: Make sure the brake caliper guide pin bolts are clean and free of debris or a binding condition may occur.

NOTICE: Do not allow the brake flexible hose to get twisted when the caliper is repositioned on the brake caliper anchor plate or damage to the hose may occur.

Relocate and support the component.- To install, tighten to 75 Nm (55 lb-ft).

- NOTICE: Make sure the caliper pin boots are correctly seated

to prevent corrosion to the guide pins.

Visual check.

Installation

- NOTE: If installing new brake pads, make sure to install all new

hardware and lubricant supplied with the brake pad kit. Refer to the brake

pad instruction sheet when applying lubricant.

To install, reverse the removal procedure.

- Visual check.

Brake Caliper

Material

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTICE: Do not allow grease, oil, brake fluid or other contaminants to contact the pad lining material, or damage to components may occur. Do not install contaminated pads.

NOTE: Removal steps in this procedure may contain installation details.

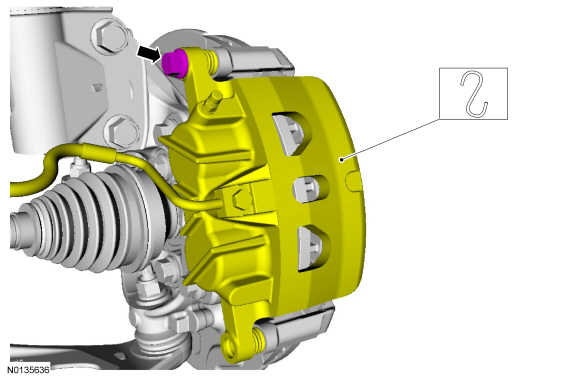

NOTE: 352 mm (14 in) brakes shown, 325 mm (13 in) brakes similar.

- Discard the specified component. Follow local disposal regulations.

- To install, tighten to 47 Nm (35 lb-ft).

- NOTICE: Make sure the brake caliper guide pin bolts are clean

and free of debris or a binding condition may occur.

NOTICE: Make sure the caliper pin boots are correctly seated to prevent corrosion to the guide pins.

- 325 mm (13 in) brakes: To install, tighten to 72 Nm (53 lb-ft).

- 352 mm (14 in) brakes: To Install, tighten to 75 Nm (55 lb-ft).

Installation

- To install, reverse the removal procedure.

- Lubricate the brake caliper flow bolt threads and new washers with clean specified brake fluid before installing the brake caliper flow bolt into the brake caliper.

- Bleed the brake caliper. For additional information, REFER to Section 206-00 for Component Bleeding.

Brake Caliper Anchor Plate

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTE: Removal steps in this procedure may contain installation details.

All vehicles

- Remove the brake pads. For additional information, refer to Brake Pads - 352 mm (14 in) Brakes or Brake Pads - 325 mm (13 in) Brakes in this section.

Vehicles with 352 mm (14 in) brakes

- Relocate and support the component.

- To install, tighten to 75 Nm (55 lb-ft).

All vehicles

- NOTE: 352 mm (14 in) brakes shown, 325 mm (13 in) brakes similar.

Discard the specified component. Follow local disposal regulations.

- To install, tighten to 165 Nm (122 lb-ft).

Installation

- To install, reverse the removal procedure.

Brake Disc

Material

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTE: Removal steps in this procedure may contain installation details.

NOTE: 352 mm (14 in) brakes shown, 325 mm (13 in) brakes similar.

- Remove the wheel and tire. For additional information, REFER to Section 204-04.

- NOTICE: Do not allow the brake caliper to hang from the brake

flexible hose or damage to the hose may occur.

Relocate and support the component. Discard the specified component. Follow local disposal regulations.

- To install, tighten the new bolts to 165 Nm (122 lb-ft).

- NOTE: If necessary, thread a M10 bolt into the brake disc removal

hole and tighten to press the disc off the hub.

Discard the specified component. Follow local disposal regulations.

- To install, tighten the new screw to 20 Nm (177 lb-in).

Installation

- Visual check. Wire brush. Clean the specified component with the specified material.

- To install, reverse the removal procedure.

Brake Disc Shield

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTE: Removal steps in this procedure may contain installation details.

NOTE: 352 mm (14 in) brakes shown, 325 mm (13 in) brakes similar.

- Remove the brake disc. For additional information, refer to Brake Disc in this section.

-

- To install, tighten to 15 Nm (133 lb-in).

Installation

- To install, reverse the removal procedure.

Brake Flexible Hose

Material

Removal

WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in Section 100-00. Failure to follow this instruction may result in serious personal injury.

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTICE: Do not allow grease, oil, brake fluid or other contaminants to contact the pad lining material, or damage to components may occur. Do not install contaminated pads.

NOTE: Removal steps in this procedure may contain installation details.

NOTE:

- With the vehicle in NEUTRAL, position it on a hoist. For additional information, REFER to Section 100-02.

- NOTICE: Make sure to protect the brake pads from contamination

from the brake fluid during the brake flexible hose installation and the

brake caliper bleeding.

- To install, tighten the brake tube fiting to 17 Nm (150 lb-in).

- To install, tighten the brake flexible hose bracket bolt to 30 Nm (22 lb-ft).

- Discard the specified component. Follow local disposal regulations.

- To install, tighten to 47 Nm (35 lb-ft).

Installation

- To install, reverse the removal procedure.

- Lubricate the brake caliper flow bolt threads and new washers with clean brake fluid before installing the brake caliper flow bolt into the brake caliper.

- Bleed the brake caliper. For additional information, REFER to Section 206-00 for Component Bleeding.

Brake System - General Information

Brake System - General Information

SPECIFICATIONS

Material

General Specifications

Torque Specifications

DIAGNOSIS AND TESTING

Principles of Operation

Brake System

Applying the brake pedal uses lever action to push a rod into the bra ...

Rear Disc Brake

Rear Disc Brake

SPECIFICATIONS

Torque Specifications

REMOVAL AND INSTALLATION

Brake Pads

Special Tool(s)

Material

Removal

WARNING:

Before beginning any service procedure in this section, refer to Safety Warnings ...

Other materials:

Information messages

Note: Depending on the vehicle options equipped with your vehicle, not

all of the messages will display or be available. Certain messages may be

abbreviated or shortened depending upon which cluster type you have.

Press the OK button to

acknowledge and remove some

messages from the informatio ...

911 Assist™

WARNING: Unless the 911 Assist setting is set on prior to a

crash, the system will not dial for help which could delay

response time, potentially increasing the risk of serious injury or death

after a crash.

WARNING: Do not wait for 911 Assist to make an emergency

call if you can do it yourself ...

Instrument Cluster and Panel Illumination

DESCRIPTION AND OPERATION

Instrument Cluster and Panel Illumination

Overview

Dimmable Backlighting

Dimmable illumination provides backlighting to certain switches and control

components when the parking lamps are on. The level of backlighting intensity is

adjusted by instrument panel dimmer switch ...